- #BACK REFLECTION LAUE METHOD UPDATE#

- #BACK REFLECTION LAUE METHOD FULL#

- #BACK REFLECTION LAUE METHOD SOFTWARE#

Xd vector along the "horizontal" axis of the detector, It is an orthonormal set of axes linked to the flat detector, X vector pointing toward the X ray source, It is an orthonormal set of fixed axes linked to the apparatus, You must understand the use of two other sets of axes: LaueX uses the usual crystallographic axes, If all the previous steps are sucessfull, you are This will help him to correct and improve the Warnings please send them to the author of the program.

#BACK REFLECTION LAUE METHOD UPDATE#

Update the variable G_HELP, giving the command to be IfĪ WEB browser is available on your system, The files spgrp.gen and scat_fact.dat respectively. Variable indicate to the program the location of

#BACK REFLECTION LAUE METHOD FULL#

You must give the correct full filenames in the Where the executable module will be stored. Modify also the value of variable DIR witch indicates the directory Replace them by theĪre given in comment for certain systems. (variables CC, CFLAGS, LFLAGS and XLIBS).ĭefault options are for IBM AIX. The libraries names which depend on your system Sources contains the source code, doc the documentation and The directory laueX has the following structure:

#BACK REFLECTION LAUE METHOD SOFTWARE#

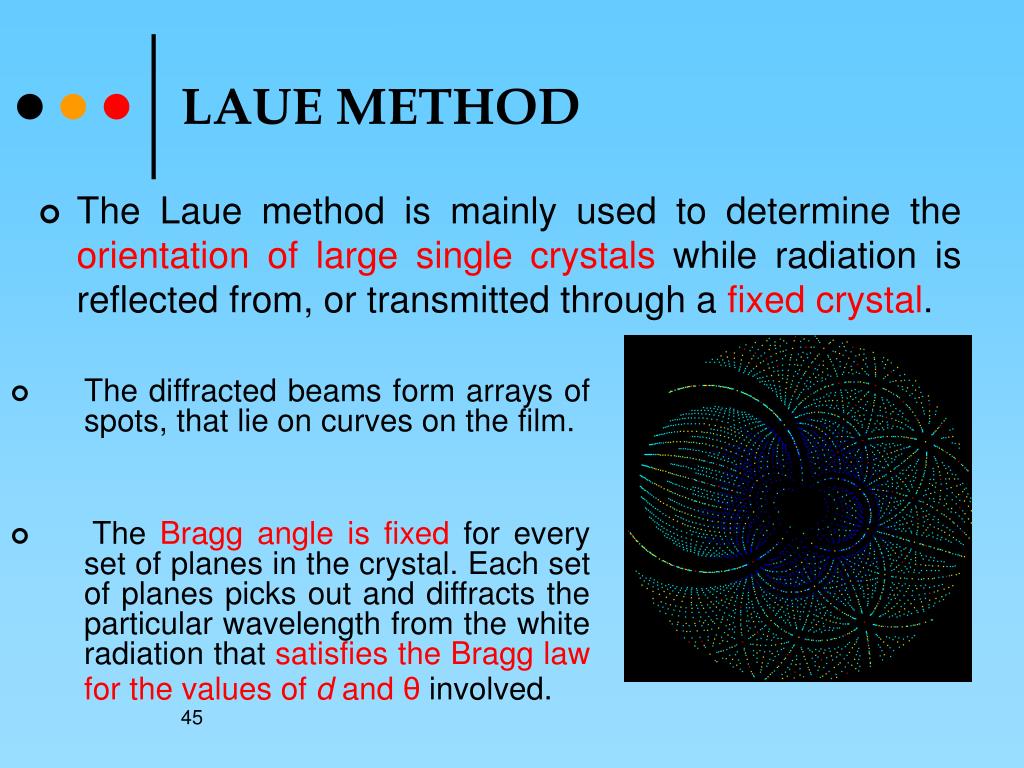

This notice is available on the Web, in the software connect to the ftp server of the laboratory:įtp> "cd pub/sincris/software/general/laueX".The program laueX is available via ftp (File Transfert Protocol) It requires X-Window and OSF-Motif libraries. LaueX is written in C language, and designed for UNIX workstations. print the simulation diagram as a Postscript.It determines the orientation of the crystal. Parameters and the position of a number of spots of index an experimental Laue diagram, by the knowledge of the cell.Whose size is proportional to the intensity. The intensities of the Laue spots and shows the result as spots When the structure of the crystal is known, the program may evaluate Orientation of the crystal and the cell parameters. LaueX is an easy to used interactive program, with a MacIntosh like Example 2: indexation of a Laue diagram.Example 1: simulation of a Laue diagram.We Recommend.Laboratoire de Minéralogie-Cristallographie associé au CNRS The Photonic Laue Systems is widely in the Semiconductor industry for Wafer fabrication: GaN Wafers, SiC Wafers,GaAs Wafers, Compound Semiconductors, Germanium Wafers, CdZnTe Wafers, and Silicon Wafers. Thanks to a beam footprint as small as <0.5mm on the sample, crystals with dimensions as small as a few millimetres can be checked in the laboratory. PSEL Laue tool delivers orientation accuracy down to 0.05 degrees, this is critical for semiconductor detectors, sapphire substrates, laser or gamma scintillation materials, ceramics and metal alloys. It will report specific angular positions for cutting or polishing crystals that will enable specific optical, magnetic or electronic transport properties. PSEL Laue tool will deliver a misorientation value against the primary 0-10 reference axis which coincides with the centre of detector and the beam position. A back reflection geometry is used to record as many Bragg reflections as possible within a single exposure onto a very low noise cooled CMOS based detector. An intense beam with typically 9-29keV energy range is delivered onto a single crystal material positioned behind the detector. The Photonic Science & Engineering (PSEL) Laue tool uses a polychromatic “white” beam configuration, passing through the centre of our detector. Laue diffraction is a powerful method for investigating crystal orientation. This solution is also ideal for replacing film-based Laue systems for industrial applications for example, monitoring for imperfections in high performance turbine blades made from single crystal advanced alloys and this is done to avoid poor creep resistance and failure of blades when at a high operating temperature. With modern synchrotron and laboratory optics able to deliver micrometre beam size, it is possible to highlight the grain orientation and strain distribution of individual grains in a polycrystalline alloy before and after tensile loading. Crystal orientation is determined from the position of the spots that are generated. This is useful if the sample is too thick or bulky for X-rays to transmit through it. The Laue back reflection mode records X-rays scattered backwards of a sample that has come from a broad-spectrum source. The Laue method helps in determining the orientation of single crystals using white radiation in a reflected or transmitted geometry.

0 kommentar(er)

0 kommentar(er)